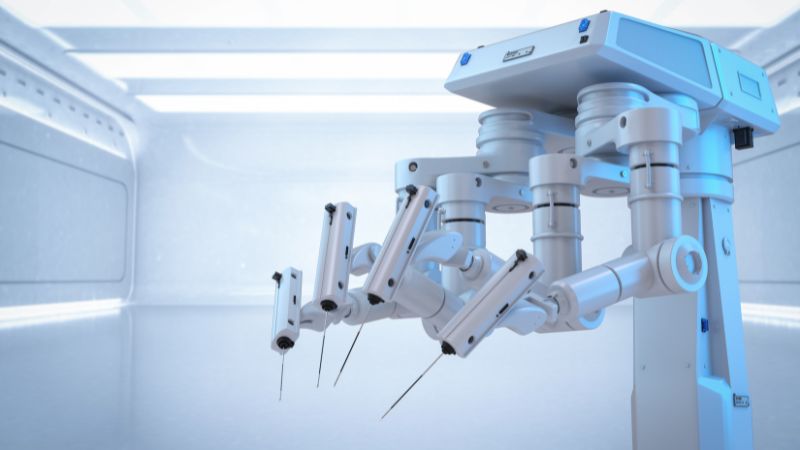

Gears for Surgical Robotics

Surgical robots are one of the important breakthroughs in modern medical technology. Since their first introduction in the 1980s, surgical robots have undergone significant development. The earliest surgical robot systems, such as the PUMA 560, were used in neurosurgery, although their use was quite limited at that time. The emergence of the da Vinci surgical system in the late 1990s marked a new stage in surgical robots. The da Vinci system provides higher precision, less trauma, and faster recovery time, making it widely used in minimally invasive surgery.

Surgical robots are important in modern medicine, mainly in the following aspects:

Improving surgical precision: surgical robots can perform small and precise movements, reduce surgical errors, and improve surgical success rates.

Reducing trauma and pain: Since surgical robots can perform minimally invasive surgery, patients have shorter postoperative recovery times and lower rates of pain and complications.

Expanding surgical capabilities: surgical robots can operate in small and hard-to-reach surgical sites, expanding the scope and capabilities of surgical operations.

Improving working conditions for surgeons: surgical robots can reduce the physical burden and fatigue of surgeons and improve surgical efficiency and quality.

Promoting remote surgery: surgical robots make remote surgery possible, and experts can perform surgery under remote guidance or personally operate robots, especially in resource-poor areas or emergency situations.

Gears for surgical robots

Surgical robots rely on a variety of gears in their precision operations, which play a vital role in the performance and accuracy of the robot. The main types of gears include:

Planetary Gears: Planetary gear systems are often used in surgical robots to drive and control the movement of the operating arm due to their high efficiency and high torque transmission capabilities.

Helical Gears: Helical gears have smooth transmission and low noise, and are often used in surgical robot parts that require precision control and smooth movement.

Bevel Gears: Bevel gears are often used in situations where the direction of power transmission needs to be changed within a limited space, such as joints and operating ends in surgical robots.

Worm Gears: Worm gear transmission systems are suitable for stable and low-speed transmission applications in surgical robots due to their self-locking characteristics and high reduction ratio.